Another possibility is where the final balance holes are drilled in relation to the rear CRANK counterweight. Maybe someone has a 64 - 65 390 flexplate to look at, that has the imprint of the crank on it, showing the notches in the back of the crank in relation to where the final balance holes are drilled. OR if I new where the final balance holes were drilled into the flexplate from a 64 - 65 390 I could try to select a MORE correctly balanced flexplate for the C-6 application. selecting a flexplate that has final balance holes drilled in the wrong location (thus introducing up to a few ounces of imbalance). I would be better off using a new flexplate without any final balance holes drilled in VS. All of the flexplates from 360's have about 2 holes partially drilled in another location. All of the flexplates from 390's have about 6 - 8 partially drilled final balance holes in the same location. I have several stock Ford FE/C-6 flexplates that would physically fit in place. Thanks for the help.I am putting a C-6 behind an already assembled 390 that has a 64 - 65 crankshaft (C4AE). Like looking at the rear of the motor (or a later model flexplate), are the balance holes at 3 o'clock, 6 o'clock or whatever from the rear counterweight. Does anyone have a 64-65 flexplate to look at and let me know what it looks like, please? It would be real nice if one could be compared to a later model flexplate to see if the indexing is the same OR maybe get an idea of where any balance holes are drilled in relation to the rear crankshaft counterweight.

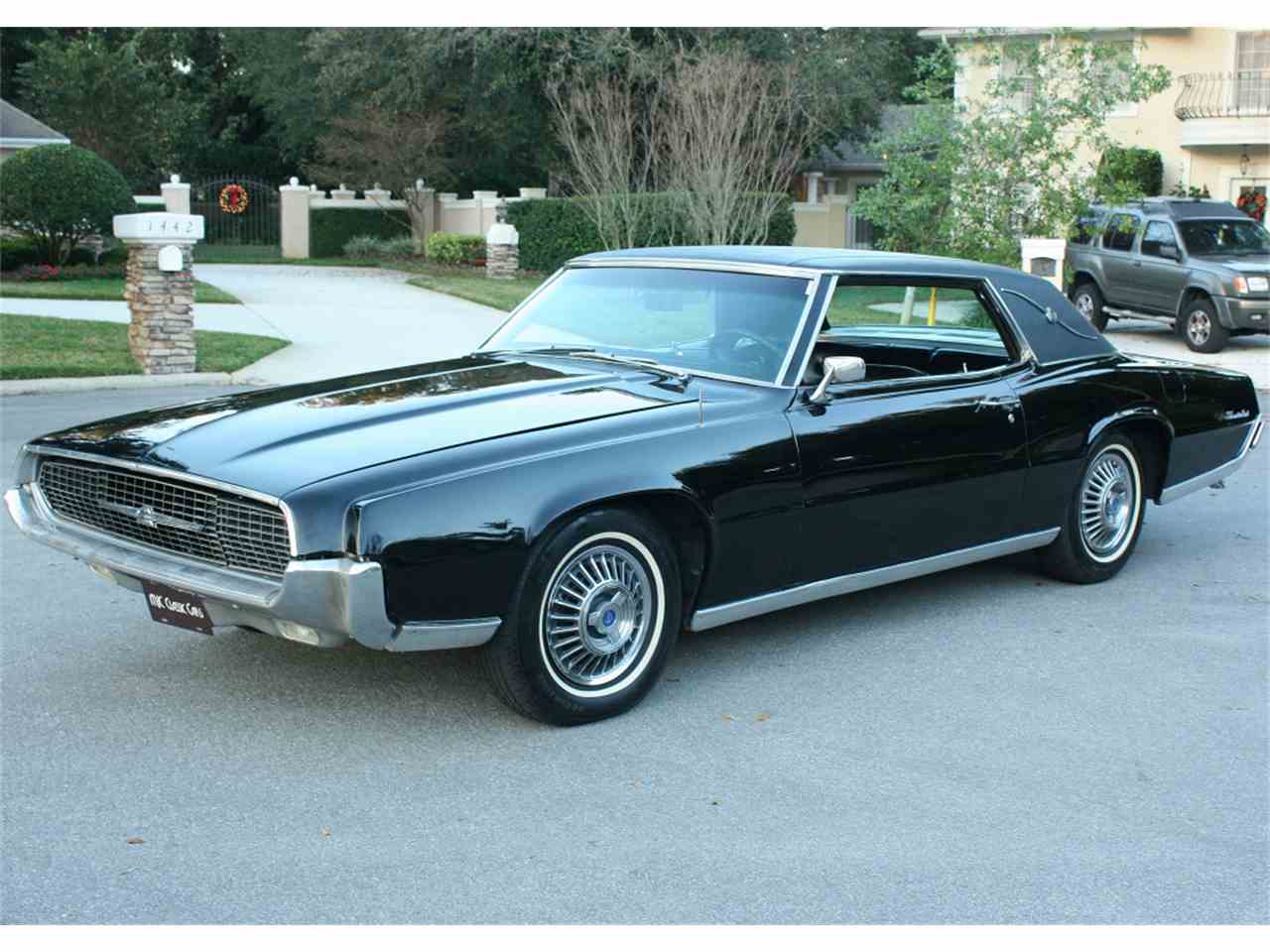

#67 thunderbird flexplate series#

I have not seen a 64 - 65 flexplate that I know of, and was wondering if the 64-65 usually has the same series of holes drilled in for balance. Usually in about the same area of the flexplate. I have noticed that the 66 and up 390 flexplates have a lot of (6-8) balance holes drilled part way thru. I am going to use an already built low rpm stock 390 with a 64-65 crank in it, and want to use a later model c-6/flexplate.

0 kommentar(er)

0 kommentar(er)